Hydraulic Systems in Auto Repair: Tools and Techniques

Hydraulic systems are behind some of the most essential functions in automotive repair, whether lifting a vehicle in the shop or bringing a car to a stop on the highway. These powerful systems quietly do the heavy lifting, and today’s automotive training graduates must know how to work with them safely and skillfully.

That’s why hydraulic training is a key part of becoming a professional technician. At CATI, students enrolled in automotive school not only learn about engines and diagnostics, but they also gain real-world experience with the hydraulic tools and systems that keep modern vehicles running smoothly.

Let’s look at what these systems are, why they matter, and how you’ll learn to master them in automotive school.

Why Hydraulics Are a Big Deal in the Shop

From brake systems and suspension to jacks and lifts, hydraulics are used in nearly every automotive service environment. These systems use fluid pressure to transfer force, offering mechanics the ability to stop, lift, press, and maneuver with incredible control.

As cars have evolved, so have the systems that power them. Today’s hydraulic systems are often paired with sensors and electronics, creating a complex network that requires not just physical skill but also diagnostic know-how. This means mechanics can’t rely on guesswork; they need training that’s hands-on, accurate, and up to date.

How Automotive Training Prepares You to Work With Hydraulic Systems

At CATI, students don’t just study hydraulic theory, they put it into practice. In our automotive training program, you’ll learn to identify, maintain, and repair hydraulic systems used in everyday automotive work.

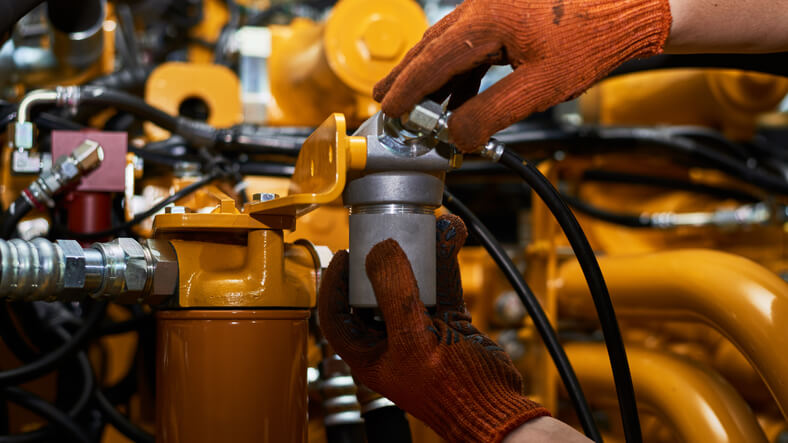

That includes mastering brake systems, safely operating hydraulic lifts, and learning how to detect fluid leaks or pressure problems before they become dangerous. You’ll also become familiar with specialty tools used in hydraulic repair, like seal drivers, flare nut wrenches, and pressure gauges.

But what makes CATI’s approach stand out is its real-world emphasis. You won’t just learn how systems work, you’ll gain the confidence to diagnose problems, explain repairs to customers, and perform jobs efficiently in a busy shop setting.

Hydraulic Repairs in Action: What You’ll Do

When a vehicle comes in with spongy brakes or power steering issues, the hydraulic system is one of the first things a trained technician inspects. At our automotive school, you’ll learn how to:

- Diagnose leaks and worn-out components

- Replace or service the master and slave cylinders

- Bleed brake lines and eliminate air from the system

- Test pressure in lifts and suspension units

- Use safe methods to lift and lower vehicles for service

These aren’t abstract skills, they’re the kinds of jobs you’ll do on your very first day in a shop. By training with industry tools and equipment, you’ll be ready to jump in with confidence when it counts.

Why Hydraulic Knowledge Sets You Apart

Mechanics who understand how to service hydraulic systems are in high demand, especially as more advanced vehicles integrate these systems with electronic controls. Hiring managers want technicians who can diagnose issues efficiently, follow safety protocols, and minimize downtime in the bay.

That’s why automotive training at CATI doesn’t just teach you what to do, it shows you how to think, work, and solve problems like a pro. You’ll finish the program ready to handle jobs in general repair shops, specialty brake service, dealership service departments, and beyond.

Do you want to explore automotive programs at CATI school?

Contact us for more information.