3D-Printed Car Parts: A New Era for Parts Specialists in 2026

TL;DR: In 2026, 3D printing car parts is moving beyond prototypes into selective real-world use—especially for tooling, brackets, trim pieces, and low-volume components. The opportunity is real, but so are the limits: safety-critical parts still require certified manufacturing, traceability, and strict quality control. For parts specialists, the biggest shift may be digital parts inventory—managing approved files, materials, and suppliers as carefully as physical stock.

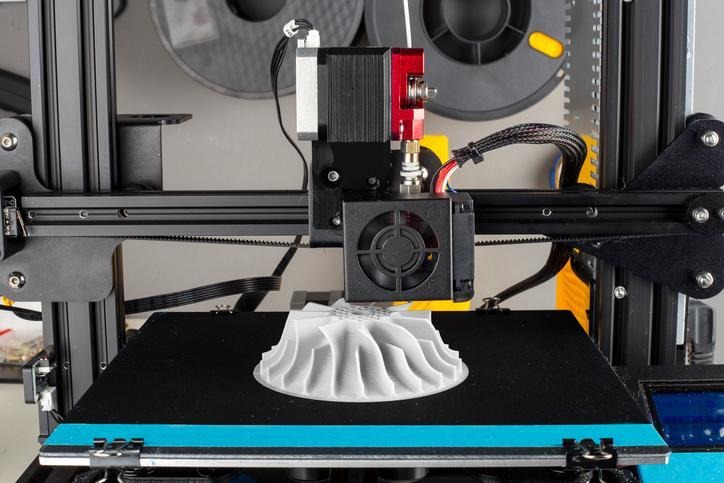

In 2026, “3D-printed car parts” doesn’t mean a shop is casually printing suspension arms between oil changes. It means something more practical—and more relevant to parts departments: certain components, tools, and low-volume parts can be produced on demand when traditional supply chains are slow, backordered, or discontinued.

This article breaks down what is already being 3D-printed, what should never be treated like a quick print job, and why parts specialists are central to quality, documentation, and supplier validation in an additive manufacturing world.

Why 3D printing matters to parts specialists (not just engineers)

A lot of people hear “additive manufacturing” and picture a giant factory. But the day-to-day impact shows up in parts departments first:

- Sourcing alternatives faster

- Verifying print-approved materials and suppliers

- Tracking revisions (version control isn’t just for software anymore)

- Documenting compliance and quality checks

In short, 3D printing isn’t replacing parts specialists. It’s giving them a new kind of inventory to manage.

Can critical car parts really be made with 3D printing?

Some can, but not all should.

Think of parts in three buckets:

Bucket A: Already common (low risk / high usefulness)

- Jigs, fixtures, and tooling used in manufacturing and repair

- Brackets and mounts (application dependent)

- Interior trim pieces and small housings

- Clips, covers, ducts (material-dependent)

Bucket B: Possible, but requires strict quality control

- Certain metal components are made with advanced industrial processes

- Structural parts in performance contexts (not casual “shop printing”)

Bucket C: Generally not suitable for casual printing

- Safety-critical components (airbag-related parts, critical suspension parts)

- Parts requiring certified manufacturing and traceability

This is where parts specialists become essential: knowing what’s allowed, what’s smart, and what’s risky.

How 3D printing helps during an auto parts shortage

Parts shortages don’t always look like “nothing is available.” Sometimes the issue is:

- A low-volume part is backordered for months

- A model is discontinued, and the supply chain dries up

- Shipping delays make timelines unpredictable

3D printing supports bridging strategies, like:

- Producing tooling faster to restart small batch runs

- Replacing hard-to-find trim or brackets while waiting for original equipment manufacturers (OEM) supply

3D printing can support stopgap and continuity strategies—especially for non-safety-critical components, when the part is validated for fit and function and sourced through approved, documented processes (often via OEM or certified partner networks).

What types of auto parts are already being 3D-printed?

Across the industry, common applications include rapid prototyping and selective production for:

- Fitment testing

- Low-volume specialty parts

- Complex shapes that are difficult to machine

Additive manufacturing’s big advantage is speed: design, test, revise, without waiting on traditional tooling.

OEMs have published real examples of advanced additive manufacturing in production and after-sales, like BMW’s large-scale use of printed tools/work aids and Porsche Classic’s on-demand approach for rare parts

Digital parts inventory: the shift parts departments can’t ignore

Here’s the future-facing concept: instead of holding every item physically, some supply chains will hold:

- A certified design file

- An approved material spec

- A qualified production partner

- A traceability record

That’s digital parts inventory, and it pairs naturally with on-demand car parts.

For parts specialists, that means more work around:

- Supplier vetting

- Revision control

- Documentation and quality assurance (QA) checks

- Returns/warranty rules (which may differ for printed components)

Do you need special training to work with 3D-printed parts?

A parts specialist doesn’t need to run a printer to be valuable, but training helps with:

- Understanding materials (polymers vs. metals)

- Fitment verification basics

- Reading part documentation and revision histories

- Knowing when a printed part is acceptable (and when it isn’t)

If a career in parts is the goal, the future is about more than memorizing part names; it’s about systems, inventory logic, and supply chain thinking. Explore CATI School and learn more about building job-ready skills with auto parts and warehousing training.

Key Takeaways

- 3D-printed car parts are increasingly used for tooling, trim, brackets, and low-volume components—not a free-for-all for safety-critical parts.

- Industrial additive manufacturing can produce complex parts, but only with controlled materials, validated processes, and traceability.

- During shortages, printing can support stopgap strategies when parts are discontinued or backordered—if fit and function are verified.

- Digital parts inventory shifts the work toward supplier vetting, revision control, documentation, and warranty rules.

- Parts specialists help decide what is acceptable to source or print—and what should stay strictly OEM-certified.

FAQ

Can critical car parts really be made with 3D printing?

Some parts can, but safety-critical components often require certified manufacturing and strict quality assurance (QA). Many current uses focus on tooling, prototypes, and select low-volume parts.

How could 3D printing help mechanics during parts shortages?

It can provide temporary or low-risk replacements for certain components and speed up tooling for small-batch runs.

What types of auto parts are already being 3D-printed?

Tooling, fixtures, trim pieces, housings, prototypes, and some specialty low-volume parts, depending on material and process.

Do you need special training to work with 3D-printed parts?

Not always to handle them—but understanding materials, documentation, and quality expectations is a big advantage.

How might 3D printing change the job of an auto parts specialist?

More digital inventory workflows, supplier verification, revision control, and documentation responsibilities.

Will 3D-printed components be as strong as traditionally manufactured parts?

It depends on material and process; industrial metal printing can be high-performance, but “strength” must be validated and application-appropriate.